Upflow Anaerobic Sludge Blanket (UASB) Reactor: An Efficient Bioreactor

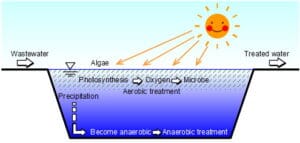

The Upflow Anaerobic Sludge Blanket (UASB) reactor is a widely used anaerobic bioreactor for wastewater treatment. It is highly efficient due to its ability to treat high-strength wastewater, recover energy in the form of biogas, and operate with minimal energy input.

Why UASB is an Efficient Bioreactor

- High Treatment Efficiency:

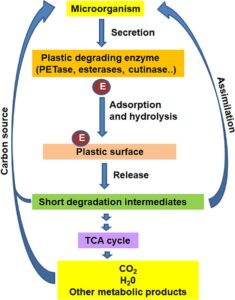

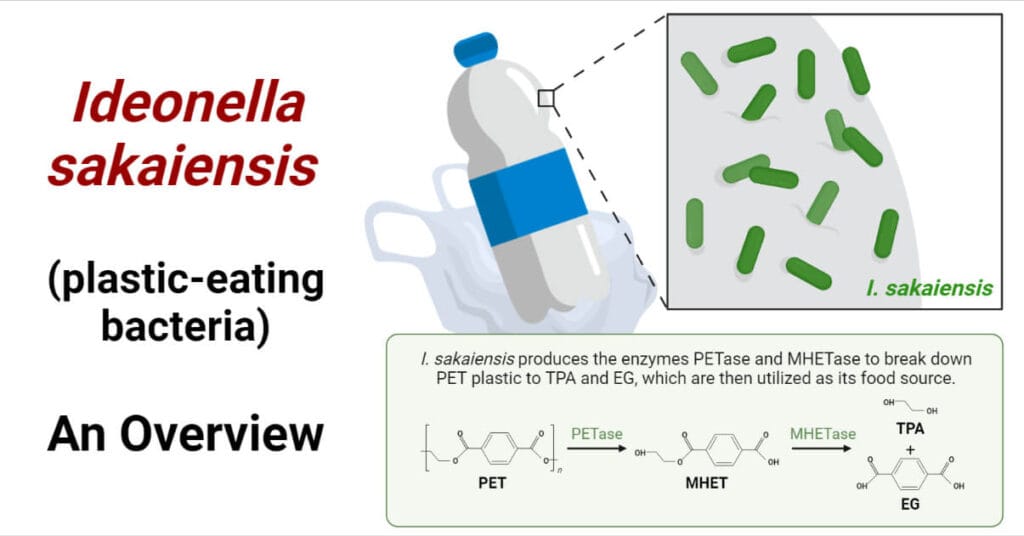

- Utilizes a dense microbial sludge blanket with a high concentration of anaerobic microorganisms for efficient organic matter degradation.

- Treats high-strength wastewater with high BOD and COD levels.

- Energy Recovery:

- Produces biogas (methane and carbon dioxide) as a by-product, which can be used as a renewable energy source.

- Low Energy Requirement:

- Operates without the need for external aeration, significantly reducing energy costs.

- Compact Design:

- Does not require a large land area compared to other treatment systems.

- Allows for scalability and retrofitting in existing facilities.

- Minimal Sludge Production:

- Generates less sludge compared to aerobic processes, reducing sludge disposal costs.

- Versatility:

- Handles a wide range of wastewater types, including municipal, industrial, and agricultural wastewater.

How UASB Works

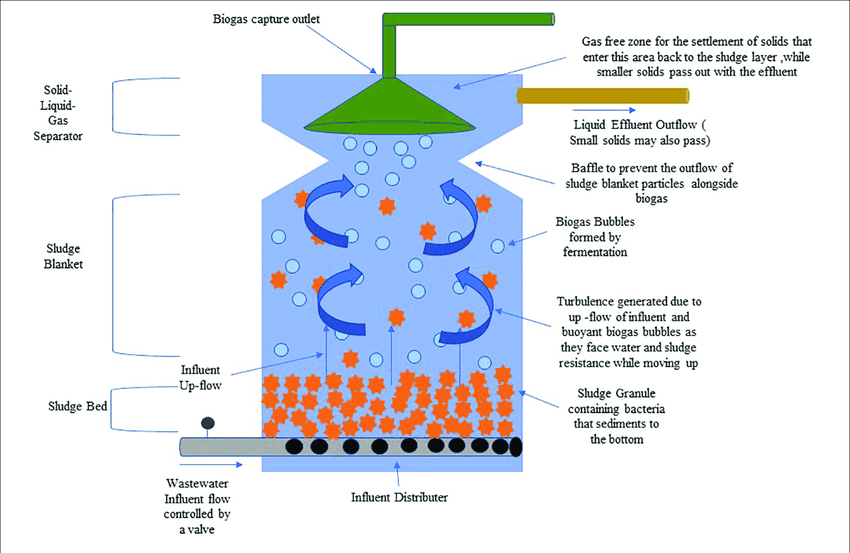

- Influent Distribution:

- Wastewater enters the reactor from the bottom and flows upward.

- Even distribution of influent ensures contact with the sludge blanket.

- Sludge Blanket:

- The dense microbial sludge blanket degrades organic matter anaerobically.

- Microbial granules provide a large surface area for biodegradation.

- Biogas Production:

- During anaerobic digestion, organic matter is converted into methane (CH₄) and carbon dioxide (CO₂).

- Biogas rises through the reactor and is collected at the top.

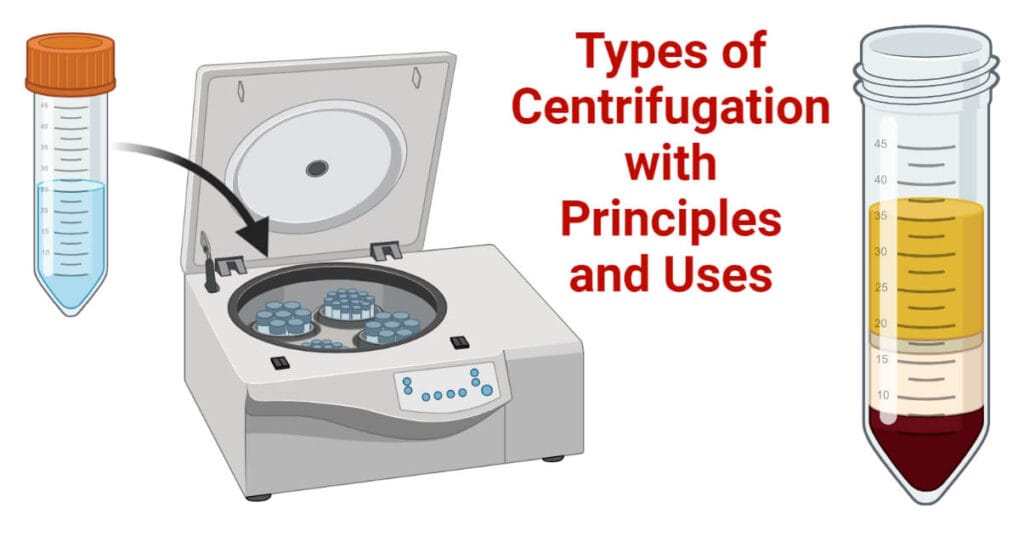

- Three-Phase Separator:

- Separates solids, liquid, and gas phases.

- Ensures sludge granules are retained within the reactor, while treated water exits.

- Effluent Discharge:

- Treated water flows out from the top of the reactor.

- May require further polishing in secondary treatment units.

Sketch of UASB Reactor

Here’s a textual description for creating the sketch:

- Structure:

- A tall cylindrical or rectangular tank with an upward flow of wastewater.

- Bottom: Influent distribution system.

- Middle: Sludge blanket zone containing microbial granules.

- Top: Three-phase separator (gas, liquid, and solids).

- Key Features:

- Inlet: Located at the bottom for influent entry.

- Sludge Blanket: Dense microbial layer for anaerobic digestion.

- Gas Outlet: Located at the top for biogas collection.

- Effluent Outlet: For treated water discharge.

Applications

- Municipal Wastewater: Efficient in treating sewage with high organic loads.

- Industrial Effluents: Treats high-strength waste from breweries, dairies, distilleries, and food processing units.

- Agricultural Wastewater: Handles manure and other organic agricultural waste.

The UASB reactor’s high efficiency, energy recovery capability, and low operating costs make it an attractive choice for sustainable wastewater treatment.