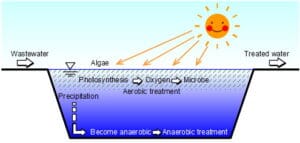

Anaerobic wastewater treatment systems operate in environments devoid of oxygen, relying on microbial communities to degrade organic matter into simpler compounds. This process is widely utilized for high-strength industrial and municipal wastewater, offering benefits such as biogas production and reduced sludge generation. The microbiology of these systems is intricate, involving various microorganisms that work in sequential stages to break down complex organic compounds.

Key Microbial Groups and Their Roles

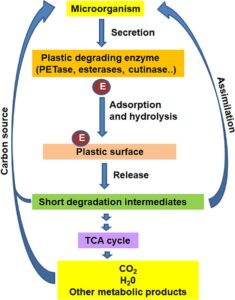

- Hydrolytic Bacteria:

- Function: Break down complex organic polymers like carbohydrates, proteins, and fats into simpler compounds such as monosaccharides, amino acids, and fatty acids.

- Enzymes Involved: Proteases, cellulases, lipases, and amylases.

- Examples: Clostridium, Bacteroides, Hydrogenophaga.

- Acidogenic Bacteria:

- Function: Ferment the simple molecules produced during hydrolysis into volatile fatty acids (VFAs), alcohols, hydrogen gas (H₂), and carbon dioxide (CO₂).

- End Products: Acetic acid, propionic acid, butyric acid, ethanol, and lactate.

- Examples: Eubacterium, Propionibacterium, Enterobacter.

- Acetogenic Bacteria:

- Function: Convert VFAs and alcohols into acetate, H₂, and CO₂. This step is critical to ensure that the products are suitable substrates for methanogens.

- Syntrophic Relationship: Often work closely with hydrogen-consuming methanogens to maintain a low hydrogen partial pressure, which is essential for thermodynamic feasibility.

- Examples: Syntrophomonas, Syntrophobacter.

- Methanogenic Archaea:

- Function: Produce methane through two main pathways:

- Acetoclastic Methanogenesis: Decompose acetate into methane and carbon dioxide.

- Hydrogenotrophic Methanogenesis: Use hydrogen and carbon dioxide to produce methane.

- Examples:

- Acetoclastic: Methanosaeta and Methanosarcina.

- Hydrogenotrophic: Methanobacterium, Methanospirillum.

- Function: Produce methane through two main pathways:

Stages of Anaerobic Digestion

- Hydrolysis:

- The first and often rate-limiting step is where large organic molecules are solubilized into smaller, soluble compounds.

- Example reaction: Proteins → Amino acids.

- Acidogenesis:

- Fermentative bacteria further degrade hydrolyzed products to VFAs, alcohols, H₂, and CO₂.

- Acetogenesis:

- Intermediate products like propionate and butyrate are oxidized to acetate, H₂, and CO₂ by acetogenic bacteria.

- The process is dependent on hydrogen removal by methanogens.

- Methanogenesis:

- The final stage is where methanogens convert acetate, H₂, and CO₂ into methane and water.

Environmental Factors Influencing Microbial Activity

- Temperature:

- Mesophilic Range (30–40°C): Common in most systems due to lower energy requirements.

- Thermophilic Range (50–60°C): Offers faster degradation rates but requires more energy.

- pH:

- Optimal range: 6.5–8.0.

- Methanogens are particularly sensitive to pH fluctuations.

- Substrate Composition:

- Balanced proportions of carbohydrates, proteins, and fats ensure stable microbial activity.

- Inhibitory Substances:

- Compounds like heavy metals, sulfides, ammonia, and excessive VFAs can inhibit microbial growth and system performance.

- Hydraulic Retention Time (HRT):

- Provides sufficient time for the complete degradation of organic matter.

Advantages of Anaerobic Systems

- Energy Recovery: Biogas (60–70% methane) can be used as a renewable energy source.

- Low Sludge Production: Compared to aerobic systems, anaerobic systems generate less biomass.

- Cost-Effectiveness: Suitable for high-strength wastewater and requires minimal aeration.

- Sustainability: Supports waste-to-energy conversion, reducing carbon footprint.

Common Anaerobic Treatment Systems

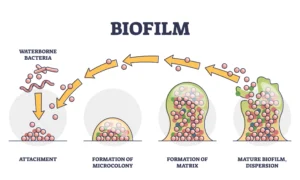

- Upflow Anaerobic Sludge Blanket (UASB):

- Features a dense microbial sludge bed for treating high-strength wastewater.

- Anaerobic Lagoons:

- Large, shallow basins offer cost-effective treatment but slower degradation rates.

- Anaerobic Filters:

- Use fixed media to enhance microbial attachment and increase treatment efficiency.

- Continuous Stirred Tank Reactor (CSTR):

- Uniform mixing ensures consistent contact between microbes and wastewater.

Anaerobic wastewater treatment systems are vital for efficient, sustainable, and eco-friendly wastewater management. Their ability to handle high-strength organic waste, reduce sludge, and produce renewable energy positions them as a cornerstone of modern environmental engineering practices.