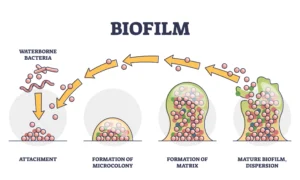

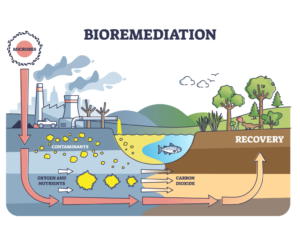

Fixed film technologies are wastewater treatment methods where microorganisms grow on a stationary surface (a “film”) and treat wastewater as it flows over or through these surfaces. These technologies are widely used due to their simplicity, cost-effectiveness, and high efficiency in organic pollutant removal.

1. Trickling Filters (TFs):

Description:

- Wastewater is distributed over a bed of porous media (rocks, plastic, or other materials) covered with a biofilm of microorganisms.

- As wastewater trickles down through the media, the biofilm degrades organic pollutants.

Key Features:

- Media: Rocks, plastic, or synthetic materials.

- Aeration: Passive (air flows naturally through the filter).

- Maintenance: Low.

- Applications: Small to medium-sized wastewater treatment plants.

Advantages:

- Simple design and operation.

- Low energy requirements.

- Resistant to shock loads.

Disadvantages:

- May require a secondary clarifier to remove sloughed biofilm.

- Limited flexibility in handling high-strength wastewater.

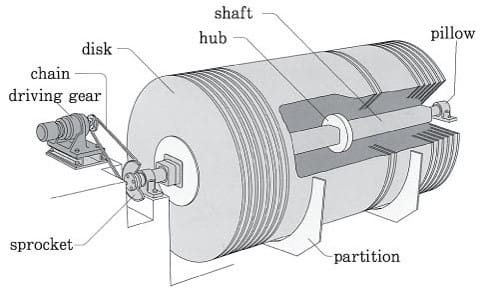

2. Rotating Biological Contactors (RBCs):

Description:

- A series of circular discs mounted on a horizontal shaft partially submerged in wastewater.

- The discs rotate slowly, alternately exposing the biofilm to wastewater and air.

Key Features:

- Media: Discs made of plastic or other lightweight materials.

- Aeration: Passive (provided during rotation).

- Applications: Small-scale and decentralized wastewater treatment.

Advantages:

- Compact and space-efficient.

- Good oxygen transfer efficiency.

- Reliable and low operational costs.

Disadvantages:

- Sensitive to low temperatures.

- Limited to low to medium organic loads.

3. Moving Bed Biofilm Reactor (MBBR):

Description:

- Utilizes free-floating plastic carriers with high surface area for biofilm attachment.

- Carriers are kept in suspension by aeration or mechanical mixing within the reactor.

Key Features:

- Media: Plastic carriers with a large surface area.

- Aeration: Mechanical or air diffusers.

- Applications: Municipal and industrial wastewater treatment.

Advantages:

- High treatment efficiency in a small footprint.

- Resistant to shock loads and variable flow rates.

- Easy to retrofit into existing treatment plants.

Disadvantages:

- Requires energy for aeration or mixing.

- Periodic maintenance of carriers may be needed.

4. Integrated Fixed Film Activated Sludge (IFAS):

Description:

- Combines conventional activated sludge (suspended growth) with fixed biofilm on carriers or media.

- Enhances biomass concentration and treatment efficiency.

Key Features:

- Media: Fixed or free-floating media added to aeration tanks.

- Aeration: Mechanical or air diffusers.

- Applications: Upgrading existing activated sludge plants.

Advantages:

- High capacity and flexibility.

- Can handle higher organic loads.

- Ideal for plant upgrades with space constraints.

Disadvantages:

- Requires additional aeration.

- High initial cost for media.

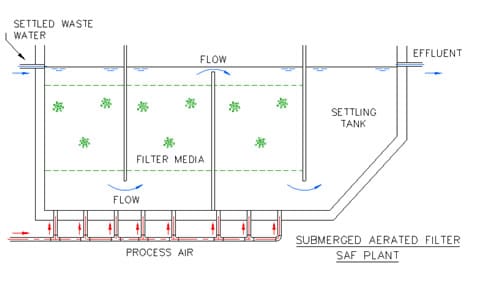

5. Submerged Aerated Filters (SAFs):

Description:

- Wastewater flows through a submerged bed of media where biofilm forms.

- Air is diffused through the bed to supply oxygen for aerobic processes.

Key Features:

- Media: Inert materials like plastic, gravel, or ceramic.

- Aeration: Air diffusers supply oxygen.

- Applications: Small-scale treatment systems and package plants.

Advantages:

- Compact design.

- High oxygen transfer efficiency.

- Low sludge production.

Disadvantages:

- Requires energy for aeration.

- Potential for clogging if not maintained.

6. Packed Bed Reactors (PBRs):

Description:

- Similar to trickling filters but typically use engineered media packed into a reactor.

- Wastewater flows either downward (gravity-driven) or upward (pumped).

Key Features:

- Media: Plastic, ceramic, or other synthetic materials.

- Aeration: Passive or active, depending on flow direction.

- Applications: Industrial and high-strength wastewater treatment.

Advantages:

- High efficiency in organic load removal.

- Minimal maintenance.

- Adaptable to various wastewater types.

Disadvantages:

- Limited by hydraulic capacity.

- May require pre-treatment for high solids content.

Comparison of Fixed Film Technologies:

| Technology | Organic Load Capacity | Footprint | Energy Requirement | Maintenance | Applications |

|---|---|---|---|---|---|

| Trickling Filters (TFs) | Low to Medium | Medium | Low | Low | Municipal wastewater |

| Rotating Biological Contactors (RBCs) | Low to Medium | Compact | Low | Low | Small-scale treatment |

| Moving Bed Biofilm Reactor (MBBR) | Medium to High | Compact | Moderate | Moderate | Industrial wastewater |

| Integrated Fixed Film Activated Sludge (IFAS) | High | Medium | Moderate to High | Moderate | Plant upgrades |

| Submerged Aerated Filters (SAFs) | Medium | Compact | Moderate | Moderate | Decentralized systems |

| Packed Bed Reactors (PBRs) | High | Compact | Low to Moderate | Low | Industrial treatment |

Fixed film technologies offer robust solutions for wastewater treatment, catering to varying organic loads, space availability, and operational constraints. Selection depends on specific treatment goals, scale, and economic considerations.