Biofilters and bioscrubbers are biological treatment systems used to remove pollutants, primarily from gaseous emissions. These technologies leverage microorganisms to degrade harmful substances, making them environmentally friendly and efficient for managing industrial waste gases. Here’s a detailed overview:

1. Biofilters

Definition:

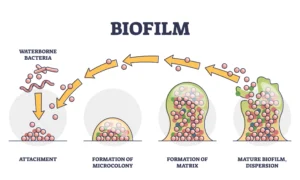

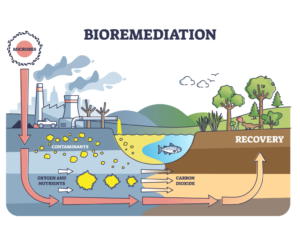

Biofilters are systems that use a bed of biologically active material, such as compost, soil, or wood chips, to treat contaminated air. Pollutants are absorbed into the biofilm layer on the surface of the filter media, where microorganisms degrade them into harmless by-products like water, carbon dioxide, and biomass.

Applications:

- Treatment of volatile organic compounds (VOCs).

- Removal of hydrogen sulfide and ammonia from industrial emissions.

- Odor control in wastewater treatment plants, composting facilities, and livestock operations.

Working Principle:

- Polluted air passes through the biofilter bed.

- Pollutants dissolve in the moisture layer on the filter media.

- Microorganisms metabolize the dissolved pollutants, converting them into non-toxic substances.

Advantages:

- Cost-effective operation.

- Minimal energy requirements.

- Environmentally sustainable.

Limitations:

- Sensitive to variations in temperature and humidity.

- Requires regular maintenance of the filter media.

2. Bioscrubbers

Definition:

Bioscrubbers are a combination of physical and biological systems that involve the scrubbing of polluted air in a liquid phase, followed by the biological degradation of the dissolved pollutants. These systems use a liquid (typically water) to absorb pollutants, which are then metabolized by microorganisms in a separate biological reactor.

Applications:

- Treatment of air streams with high concentrations of VOCs or soluble inorganic pollutants.

- Effective in removing hydrogen sulfide, sulfur oxides, and nitrogen oxides from industrial emissions.

Working Principle:

- Polluted air passes through the scrubber, where a liquid absorbs the pollutants.

- The liquid containing the dissolved pollutants is transferred to a bioreactor.

- Microorganisms in the bioreactor break down the pollutants.

- The clean liquid is recirculated to the scrubber.

Advantages:

- Capable of handling high pollutant concentrations.

- It can treat water-soluble pollutants effectively.

- Operates under controlled conditions, improving efficiency.

Limitations:

- Higher initial setup costs compared to biofilters.

- Requires continuous monitoring and maintenance.

Comparison of Biofilters and Bioscrubbers

| Feature | Biofilters | Bioscrubbers |

|---|---|---|

| Pollutant Type | Gaseous pollutants | Soluble pollutants in the liquid phase |

| Complexity | Simpler design | More complex with a bioreactor |

| Cost | Lower setup and maintenance cost | Higher initial investment |

| Efficiency | Better for low to moderate loads | Effective for high pollutant loads |

| Applications | Odor control, VOC treatment | VOCs, acid gases, ammonia |

Biofilters and bioscrubbers represent sustainable approaches to controlling air pollution. Their selection depends on factors such as the nature and concentration of pollutants, operational costs, and site-specific requirements. Both systems play vital roles in mitigating industrial emissions, contributing to cleaner air and a healthier environment.